- Home

-

Solutions

-

Leak Seal

Seal leaks in concrete or masonry with crack injection and curtain grouting of our Prime Flex polyurethanes and AR acrylate resins. Prime Resins offers superior solutions for stopping leaks in every type of environment.

Read More

-

Soil Stabilization

Sound concrete relies on a sound substrate. Stabilize soils and fill voids with our polyurethane and acrylate foams and gels. We make chemical grouts for permeation and compaction grouting in wet and dry conditions.

Read More

-

Slab Lifting & Stabilization

Slab lifting and slab stabilization with polyurethane foams offers many advantages over traditional mudjacking. Only Precision Lift is engineered to tackle underlying issues and slab lifting with precise, dependable results.

Read More

-

Floor Repair & Joint Protection

Spalled concrete is concrete that is chipped, cracked and deteriorating. This often happens at a joint.

Read More

-

Seawall Repair

You can repair a seawall or bulkhead with Prime Resins chemical grouts: fill voids, stabilize loose soil and seal leaks at a fraction of the cost of wall replacement.

Read More

-

Structural Repair / Bonding & Anchoring

The need for crack repair in concrete structures can be caused by many different factors. Damage can occur to the concrete in situations where direct impact puts stress on one area of the structure.

Read More

-

Highway & Bridge

The geotechnical needs of DOTs and other agencies responsible for roads and bridges are vast. Issues include: Culvert repair Soil stabilization Void filling Concrete slab lifting Sinkhole remediation Slope control Slough control in tunneling

Read More

-

Waterproofing & Secondary Containment

Protecting concrete usually means shielding it from the elements of nature or from harsh manmade chemicals. But it’s not just concrete that needs such protection. Corrugated metal pipe, steel surfaces, material hoppers, rail cars and masonry all can come in contact with corrosive or abrasive materials or harsh conditions.

Read More

-

Leak Seal

-

Products

-

Leak Repair

-

Soil Improvement

- Soil Stabilization

- Slab Lifting

- Structural Repair / Bonding & Anchoring

- Pumps

- Dispense Guns & Applicators

-

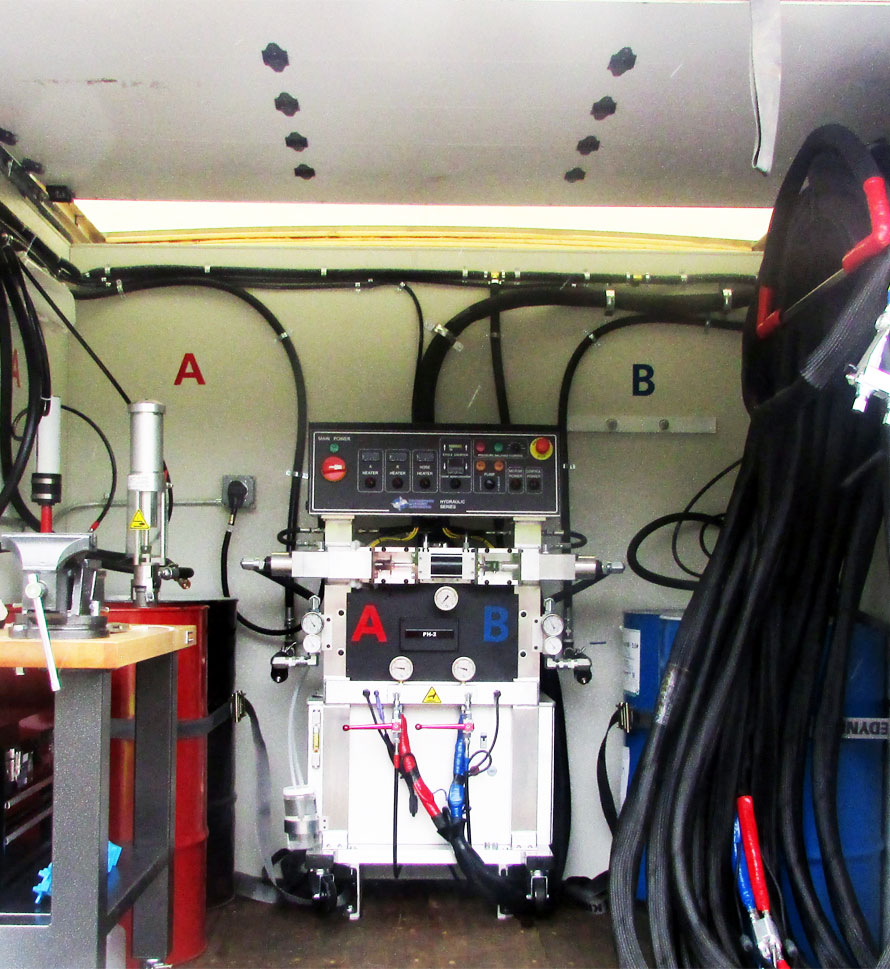

Turnkey Trailer Rig

Are you ready to hit the ground running doing concrete leveling with polyurethane foam? Prime Resins offers the industry’s best suite of products for lifting concrete as a turnkey, fully equipped trailer rig.

Read More

-

Accessories (General)

- 3/4" expendable drive point

- 3/8" and 3/4" soil probes

- Cartridge / Port Connectors and Mixers

- Conduit Seal Kit

- DM500 Divorced Mix Manifold

- Eco Flush

- F Valve

- Flush Wand

- Grout Needle Kit

- High Pressure Control Valve

- High Pressure Mechanical Ports

- Kick Fast

- Low Pressure Plastic Ports

- PR11 TEA (used w/ PR10 ACLM)

- PR12 APSF catalyst (used w/ PR10 ACLM)

- PR17 LYTX

- Prime Kat

- Prime Plug

- Prime Solvent CGC

- Oakum

- Soil pipe jack

- Stainless Steel Grout Needle & Kit

- StainShield

- Wall Stinger Nozzle

-

Soil Grouting Accessories

- Pipe Coupler

- Pipe Coupler Ferrule

- Buttonhead Coupler - Straight

- Buttonhead Fittings

- SG 3/4" Expendable Drive Tip

- SG 3/4 Rod - 39" Base

- SG 3/4 Rod - 39" Connector

- SG 3/4 Rod - 19.5" Base

- SG 3/4 Rod - 19.5" Connector

- SG 3/4 Fitting - Pipe to Buttonhead

- SG 3/4 Fitting - Buttonhead Fitting

- IL 1/2" Drive Point

- IL 1/2" rod - 39" base

- IL 1/2" rod - 39" connector

- IL 1/2" Fitting Buttonhead

- SG 3/4" Fitting - Buttonhead Coupler

- SG 3/4" Slotted Drive Tip

- SG 3/4 Drive Head

- Modified Pipe Jack Soil Grouting

- SG 3/4 Fitting - Buttonhead Coupler

- Pagani DPM30 Penetrometer

- IL 1/2" Fitting - Buttonhead to Connector Rod

- IL 1/2" Rod to Rod Coupler Fitting

- High Pressure Flow Control Valve

- Buttonhead Coupler - 90°

- Buttonhead Clamp Kit

- Floor & Joint Repair

- Waterproofing & Secondary Containment

-

Leak Repair

- News

- Downloads

-

Tools

-

Case Studies

Prime Resins takes pride in its ability to find the right solutions to the problems facing our customers. Here are some examples of customers’ successful jobs:

Read More

-

Prime Practices

-

Videos

-

Estimating Tools & Info.

-

Why us?

The superior quality of products at a fair price, our consultative approach, and our unparalleled technical support set Prime Resins apart. Learn more about the Prime difference.

Read More

-

Product Types & Typical Uses

-

Looking for a contractor?

-

Certifications

-

Case Studies

- Contact

Lift and level your concrete with Precision Lift foam

Lift and Level Concrete

If you have a sinking driveway, a sunken patio or uneven pool deck, we have a solution for you. Precision Lift polyurethane foam can lift your concrete back to level. In a fraction of the time and the mess of mudjacking or replacement, a crew can fix your sunken concrete. And it’s an eco-friendly choice: the polyurethane is completely inert when installed.

Cost of doing nothing

Uneven concrete creates a trip hazard. That means liability for you. Uneven concrete slabs will eventually break. A simple leveling job is now more complicated. If the concrete breaks in too many places, your only option will be replacement. That is expensive and takes weeks to fully cure. Do you really want to go a month without your driveway?

Fix the underlying problem

Fundamentally, concrete sinks because there is a problem with the soil underneath it. Maybe the soil wasn’t compacted well enough originally. It could be there was a lot of organic matter in it that has now broken down. Or perhaps there is an erosion issue. Leveling your concrete with structural polyurethane foam will fill any voids, compact the soil and lift the concrete. This method is known by several names: foam jacking, poly jacking, poly lifting, foam lifting or simply slab lifting with foam.

Precision Lift structural polyurethane foam can be used to lift and level:

- Cracked and uneven driveways

- Unlevel garage floors

- Sunken patios

- Settling interior concrete floors

- Sinking steps and walkways, a trip hazard

- Uneven pool decks

- Uneven sidewalks, a trip hazard

How does it work?

Two parts of the polyurethane formulation mix in the dispensing gun, creating a chemical reaction. This reaction causes a rapid transformation of the liquid into a rigid, structural foam that is unaffected by water. The rapid expansion creates hydraulic lift. If the proper density of foam is used, there should be no shrinkage of the foam. We recommend nothing less than a 3.5-pound foam for residential work. The result is precise lift and the concrete can be used immediately when the crew if finished.

Polyjacking (foam) vs Mudjacking (cement-based material)

Sometimes mudjacking is the right choice. But if access is limited, the project is small, the soil is settling, there are underground structures in place, or aesthetics are a chief concern, leveling your concrete with foam may be the best option. Here are some factors to weigh:

|

Facts |

Precision Lift |

Mudjacking |

|

Unit Weight |

3.5 to 12 lbs/cubic ft. |

150 lbs/cubic ft. |

|

Set Time |

15 minutes |

Hours to days |

|

Drill Hole |

3/8″ |

1.5″ to 2″+ |

|

Shrinkage |

None |

Yes |

|

Equipment |

One vehicle for materials, equipment |

Multiple trucks |

|

Temperature |

Can be installed in any climate |

Limited use below |

When polylifting is the right choice, one example

Uneven pool decks are a common problem. Pool installers are often reluctant to tamp the dirt around the pool too hard to avoid putting stress against the pool structure. This can mean that soil settles over time and with the weight of the concrete pool deck. The result is an uneven pool deck. It doesn’t look good and creates trip hazards. Foam lifting is really your only option besides replacement. Mudjacking or concrete jacking with cement adds huge weight that can crush below-deck plastic piping and put undue weight against the pool walls.

Proven Technology

Slab lifting with foam, or polylifting, as a technology is more than a decade old. Millions of pounds of polyurethane foam support structures worldwide. Among those are thousands of successful Precision Lift projects. This ranges from walkways, driveways, pool decks and patios across the U.S. and Canada to railroad lines in China and Mexico and manufacturing plants in Brazil. This is proven technology with a long, successful track record.

Don’t make your problem worse

Your concrete is sinking for a reason. It will likely just get worse the longer you delay. Now is the time to fix your concrete.

Let us solve your problem

Call or email us today to find a manufacturer-trained contractor in your area: 800-321-7212 or info@primeresins.com. If you prefer, fill out the form found here and we’ll contact you.